Why Ceramic Finishing Is the Ultimate Service for a Perfect End Up

Ceramic layer has actually arised as a leading remedy for those seeking a flawless coating for their lorries, many thanks to its exceptional resilience and safety features. What elements really established ceramic finish apart?

What Is Ceramic Coating?

When applied correctly, ceramic layer produces a hydrophobic surface area that fends off water and dust, making it simpler to clean up and preserve. Unlike typical waxes or sealants, which usually supply short-lived protection, ceramic coatings can last for numerous years, relying on the product top quality and application method. The process of using ceramic layer calls for meticulous preparation, including thorough cleansing and in some cases repaint modification, to make certain ideal bonding and effectiveness.

Ceramic coverings are not limited to automobile surface areas; they can also be utilized on different products, including glass, steel, and plastics, offering a functional remedy for boosting security. Generally, ceramic finish stands for a significant innovation in surface protection innovation, integrating both practical and visual advantages for a large variety of applications.

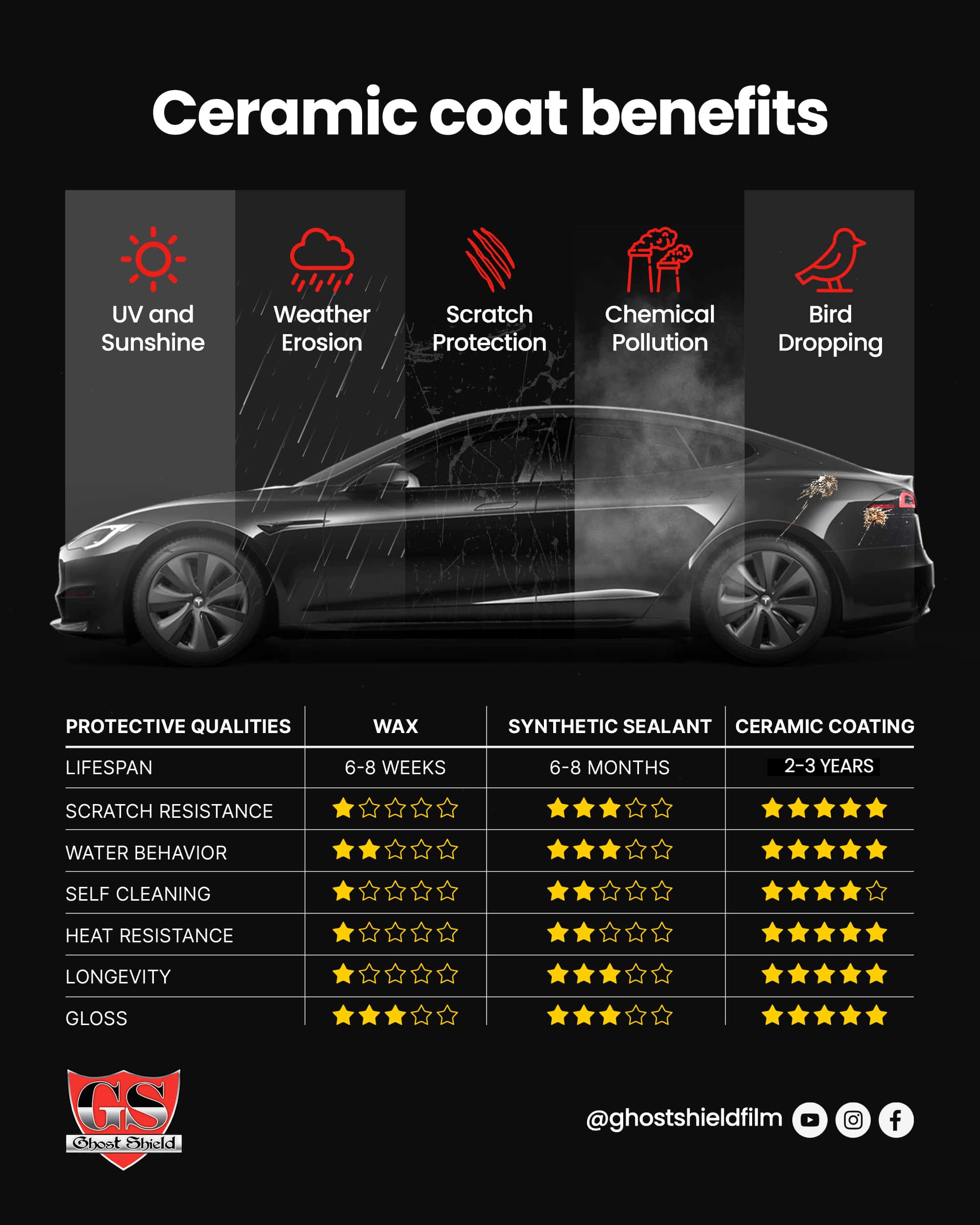

Advantages of Ceramic Layer

While many surface area defense alternatives exist, the benefits of ceramic coating stand apart due to its distinct residential or commercial properties and lasting efficiency. One of the primary advantages is its outstanding durability. Ceramic Coating Philadelphia. Unlike conventional wax or sealers that need frequent reapplication, ceramic coverings provide a durable layer that can last for numerous years, dramatically reducing upkeep initiatives

An additional remarkable advantage is enhanced defense versus environmental impurities. Ceramic finishings create a hydrophobic surface area that repels water, dust, and different contaminants, making it simpler to clean. This feature not only maintains the automobile's look however likewise reduces the risk of rust and oxidation, particularly in rough weather condition problems.

Additionally, ceramic finishes use superior resistance to UV rays, preventing fading and degradation of paint over time. This UV defense is essential for preserving the aesthetic worth of lorries and surface areas revealed to direct sunlight.

In addition, the glossy coating accomplished with ceramic finish enhances the total visual charm, offering surfaces a showroom-quality luster. Generally, ceramic finishes stand for a significant improvement in surface security modern technology, offering long-lasting benefits that accommodate both visual and practical demands.

Just How It Works

Comprehending the scientific research behind ceramic layers exposes how they offer such remarkable security and durability. At its core, a ceramic layer is a liquid polymer that chemically bonds with the vehicle's manufacturing facility paint. This bonding creates a safety layer that is both oleophobic and hydrophobic, repelling water, dirt, and oil. The primary component of a lot of ceramic layers is silicon dioxide (SiO2), which is stemmed from quartz. This compound contributes to the coating's solidity and resistance to scrapes, UV rays, and ecological pollutants.

The application procedure entails several steps, consisting of surface area preparation, which is essential to achieving ideal attachment. As soon as applied, the layer undertakes a healing process, throughout which it hardens and develops a semi-permanent bond with the paint surface area. This bond is what differentiates ceramic finishings from traditional waxes and sealers, offering a longer-lasting safety barrier that can withstand for years.

Additionally, the thickness of the covering can enhance its protective top qualities, ensuring that it can stand up to rough problems. Eventually, the science of ceramic layers incorporates advanced products with cutting-edge application techniques to deliver an unequaled level of protection and visual enhancement for automobiles.

Comparison With Conventional Approaches

When contrasted to standard paint protection techniques such as sealants and waxes,The advantages of ceramic finishings end up being especially evident. While waxes supply a momentary shine, typically lasting a couple of weeks to a number of months, ceramic finishings offer a lasting safety layer that can withstand for several years. This toughness dramatically reduces the frequency of reapplication, making ceramic coatings a much more cost-effective solution over time.

In addition, conventional approaches often call for substantial prep work and numerous applications to achieve a satisfactory level of defense. In contrast, ceramic finishings bond at a molecular degree with the automobile's surface area, developing a robust guard against ecological impurities like UV rays, acid rainfall, and road salts. This bond enhances the lorry's resistance to scrapes and swirl marks, which prevail with traditional waxes and sealants.

Moreover, the hydrophobic buildings of ceramic finishings drive away water and dirt, causing easier cleansing and maintenance. In comparison, wax and sealant-treated surfaces can attract gunk, demanding even more regular washing - Ceramic Coating Philadelphia. On the whole, ceramic finishings not only provide exceptional defense but additionally supply an extra visually appealing and enduring surface, developing them as the favored choice for discerning automobile proprietors

Application and Upkeep Tips

Making use of a foam applicator, apply the layer in little areas, adhering to the manufacturer's standards relating to density and overlap. Allow adequate curing time between coats, normally 1 day, to ensure correct bonding. After application, it is crucial to prevent exposure to water or extreme elements for a minimum of visit the website a week to permit the finish to fully cure.

In addition, using a ceramic upkeep spray can hop over to these guys improve the covering's hydrophobic residential properties and long life. Normal examinations for any kind of indicators of wear will certainly aid preserve the layer's honesty and preserve that beautiful surface.

Verdict

In conclusion, ceramic coating arises as an exceptional choice for attaining a flawless vehicle surface. By forming a durable bond with factory paint, ceramic finishing effectively shields versus scratches, UV rays, and environmental pollutants.

Comments on “Testimonials and Testimonials from Delighted Clients of Ceramic Coating Philadelphia”